ROD BEDS

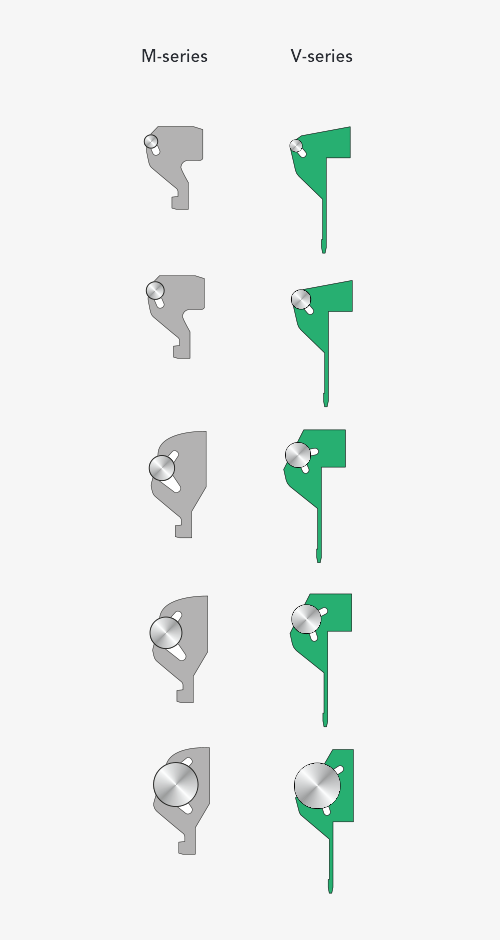

APPLICATION-RELATED DESIGNS

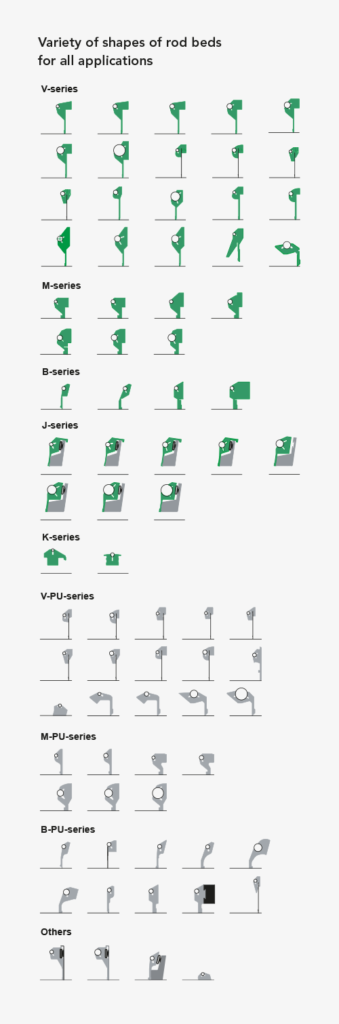

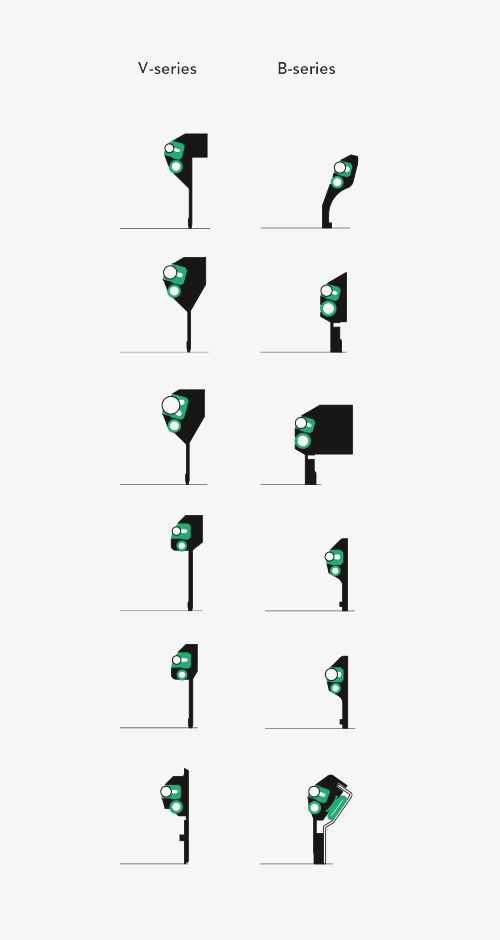

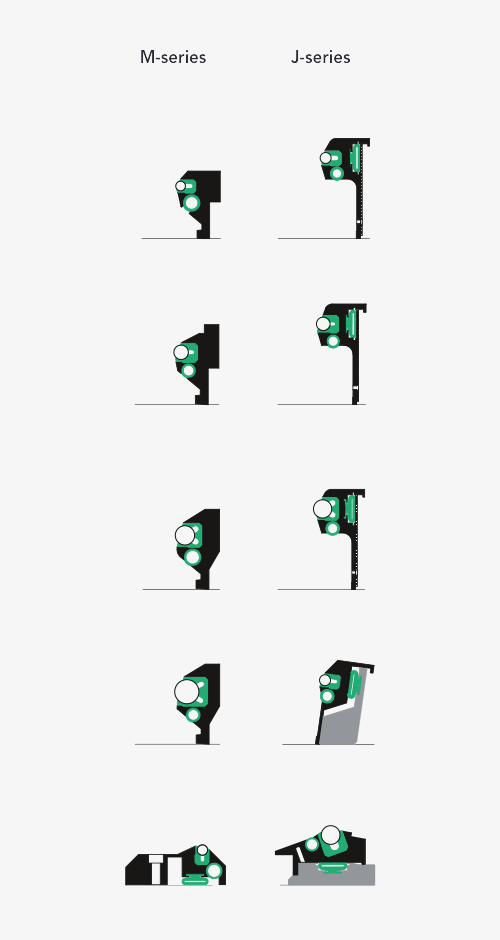

Varying requirements on metering systems and manufacturer-specific construction of coating stations have resulted in a variety of rod holder types. Generally, systems feature one or two metering rod diameters. In individual cases, up to five different diameters are possible. This is also the reason for the variety of different rod holders.

Three things are decisive for the specification of the rod beds:

- Specified design principle

- Rod diameter

- Material

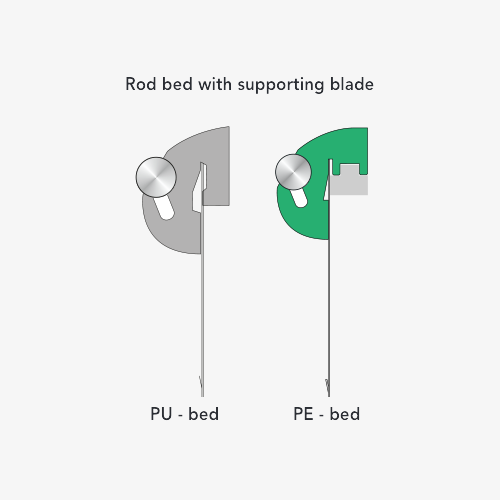

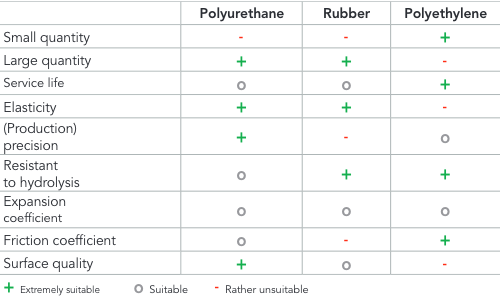

Since design principle and rod diameter are predefined, the material is an important criterion for the properties of the rod bed. Today, as a rule, Polyurethane (PU) or Polyethylene (PE) are used; older systems frequently still have rod beds made of rubber.

Depending on the material there are different manufacturing processes:

- PU and rubber = molding or extrusion process

- PE = usually milling and planing process

The production method and specific material properties offer different advantages. Finding the optimal material depends largely on the individual requirements. However, there is a trend towards rod beds made of PE.

THE RIGHT MATERIAL FOR EVERY PROCESS

Polyethylene rod beds

- Machining process

- Low friction coefficient

- Resistant to hydrolysis

- Flexible in design

- Ideal for special shapes

- Allows extended service life

Polyurethane rod beds

- Molding process

- Adjustable hardness from 55° – 97° shore A

- High elasticity

- High mechanical / dynamic load capacity

- High surface quality

- High resistance to mineral oils, greases, petrol, ozone, UV and high-energy radiation

Learn more about+ Close-

ROD BEDS

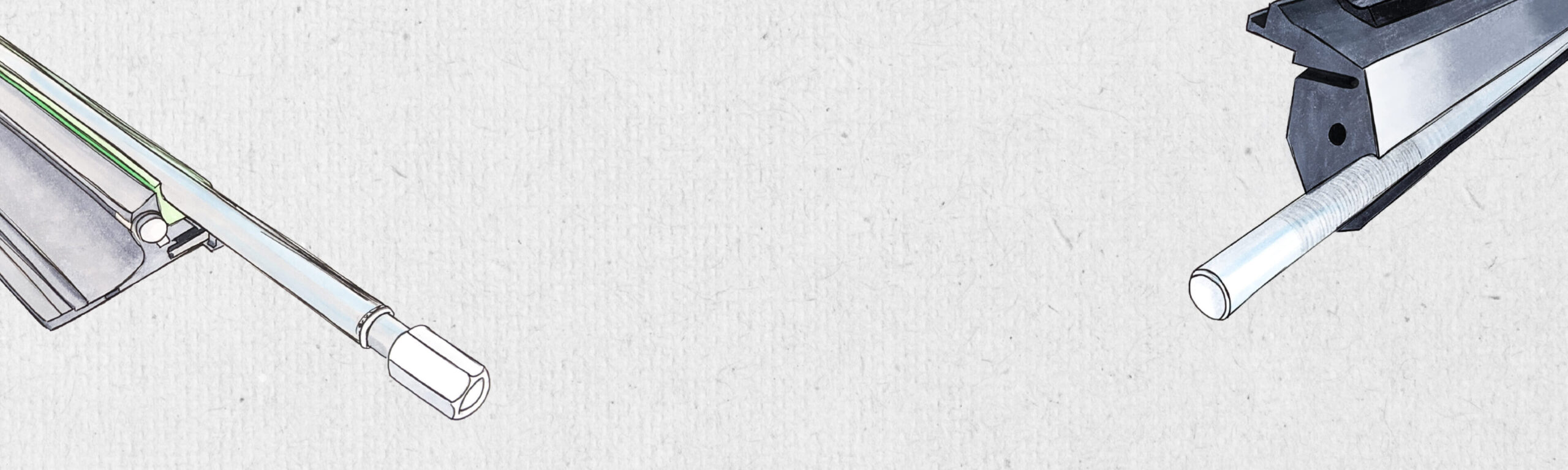

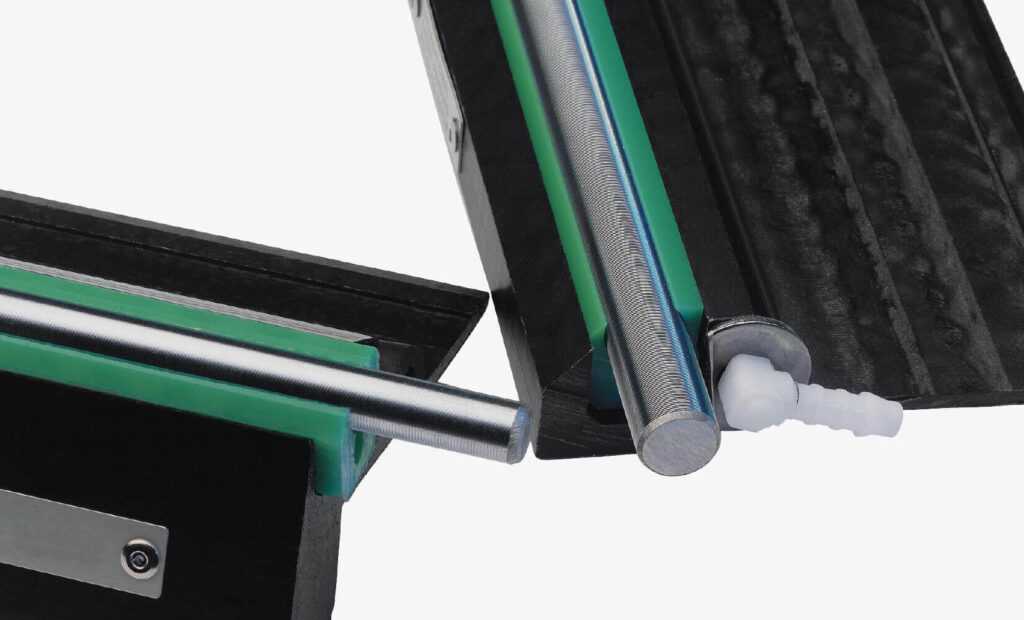

WITH COMBI SYSTEM CS

WEAR PARTS COSTS CUT IN HALF

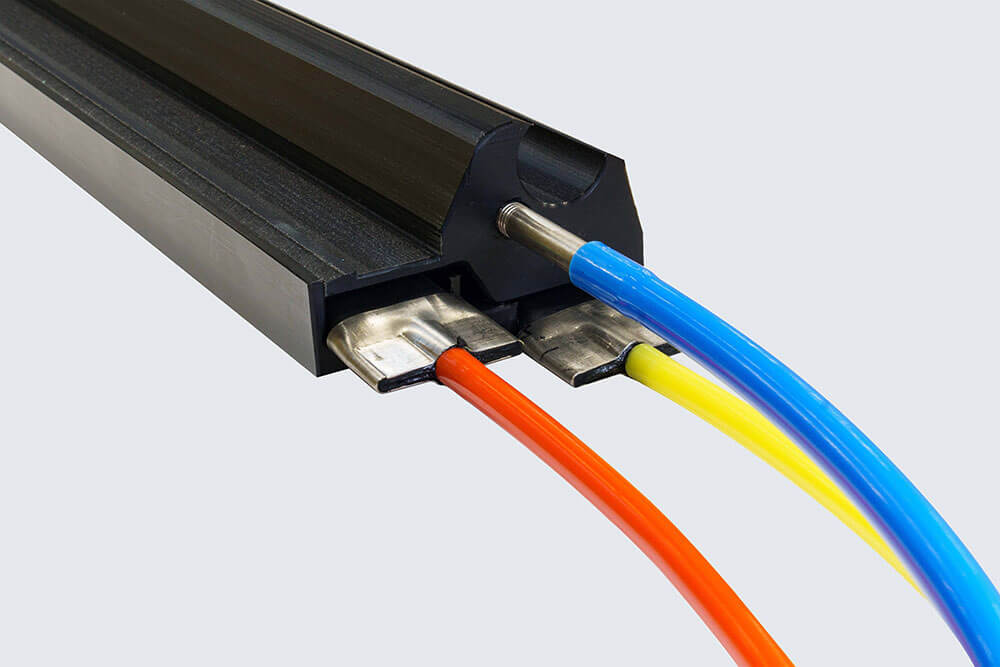

We take a holistic approach to our rod metering system. This means: In addition to rod geometry and material, we also think about the design of the rod bed. This led to the development of the Combi System CS. This multi-part rod system significantly reduces wear costs and thus increases the efficiency of paper production.

The Combi System CS offers cost reductions in the area of the metering system, increased service life due to material improvements, and optimized operating conditions. All in all, this results in a new level of efficiency that ensures clear competitive advantages.

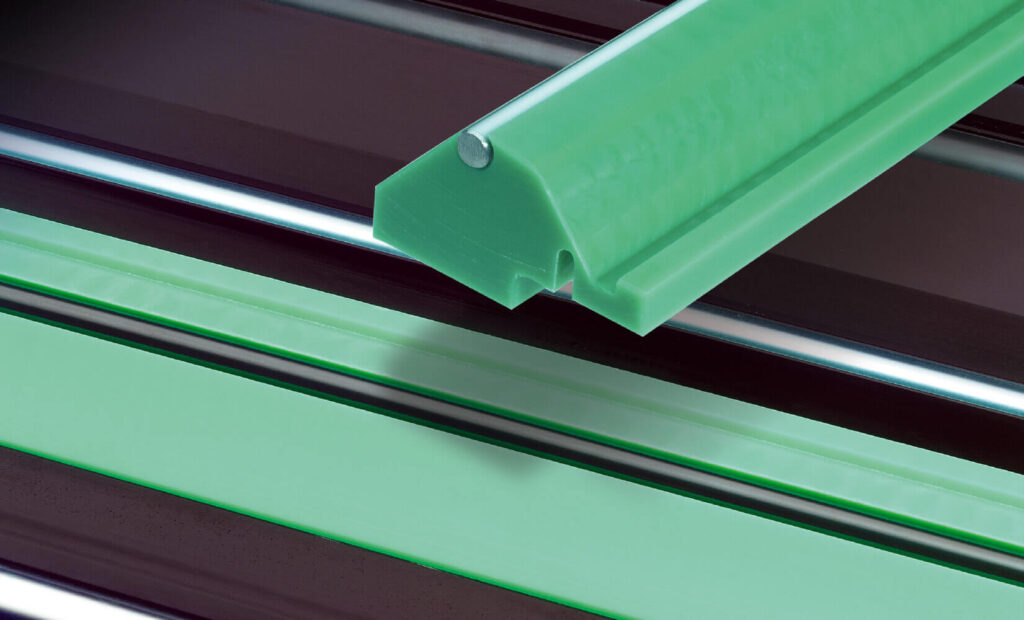

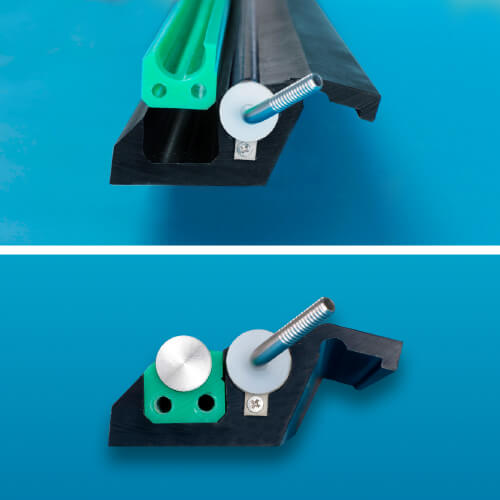

Two parts – two advantages

Our technological concept is as simple as it is effective: We divide the rod bed in two parts. Only the small and therefore cost-effective insert is changed. The holder, which is shaped to match the metering systems, remains in the machine and rarely needs to be replaced. This cuts the wear parts costs for rod beds roughly in half.

A further advantage of the Combi System CS is reduced replacement time, since the insert can be installed and removed with the metering rod inserted. This in turn results in reduced waste during the changing process.

EASIER HANDLING

The optimal material: Polyethylene

The insert is made of high-quality material. Two alternatives are available:

- Extruded material for optimal economic efficiency

- Milled version for maximum precision

APPLICATION EXAMPLE: FILMPRESS

APPLICATION EXAMPLE: DIRECT COATING

Minimizing edge wear

Direct application of abrasive coating media results in heavy wear in the edge areas of the metering rods, even if the boards are relatively thin. In the worst case, the metering rod runs for only a few hours. Our complete metering system features adjustable contact pressure that is applied on the metering rod in the edge area: Since the length of the pressure hoses is adjustable, they can be positioned in such a way that they end at a defined point before the edge. Thus, the pressure is evenly distributed over the entire rod bed and is actually not increased towards the edge.

Easy handling – quick change

Further savings result from the easy handling during change. Time-consuming cleaning of the rod beds etc. is no longer necessary. The insert is simply snapped into the holder without requiring any tools.

Learn more about+ Close-

Rod beds with

Clever System CLS

Versatile and application-optimized

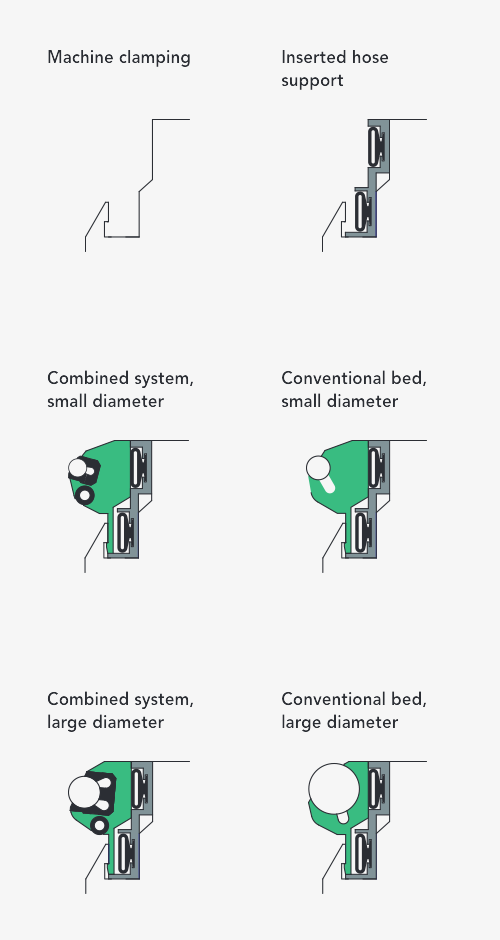

The metering system Clever System CLS combines the advantages of existing concepts in the field of rod beds. The system consists of a hose support, which contains both the pressure hose and the clamping hose, and the actual rod bed.

It is possible to use conventional rod beds as well as the combined system with low-cost rod holder in the usual diameter range. The rod bed and the hose support can be easily changed individually or together. In case of a batch-related change, for example, where time is of the essence, only the rod bed including the rod shaft is removed and a newly prepared device is installed.

If the coater needs to be cleaned, the hose support can be removed just as easily so that the rod bed can also be treated with a high-pressure unit without damaging the pressure hoses and clamping hoses.

Meanwhile, the system has become fully established in a wide variety of coaters.

Learn more about+ Close-