QUICK COUPLINGS

QUICK AND RELIABLE ROD CHANGE

Changing metering rods on running machines is comparable to a Formula 1 pit stop: everything must be done as quickly as possible. Because during a rod change, each additional minute results in increased waste. For this reason, so-called quick couplings are applied, though they do not always live up to their name. Frequently they involve conventional quick couplings from other branches of industry.

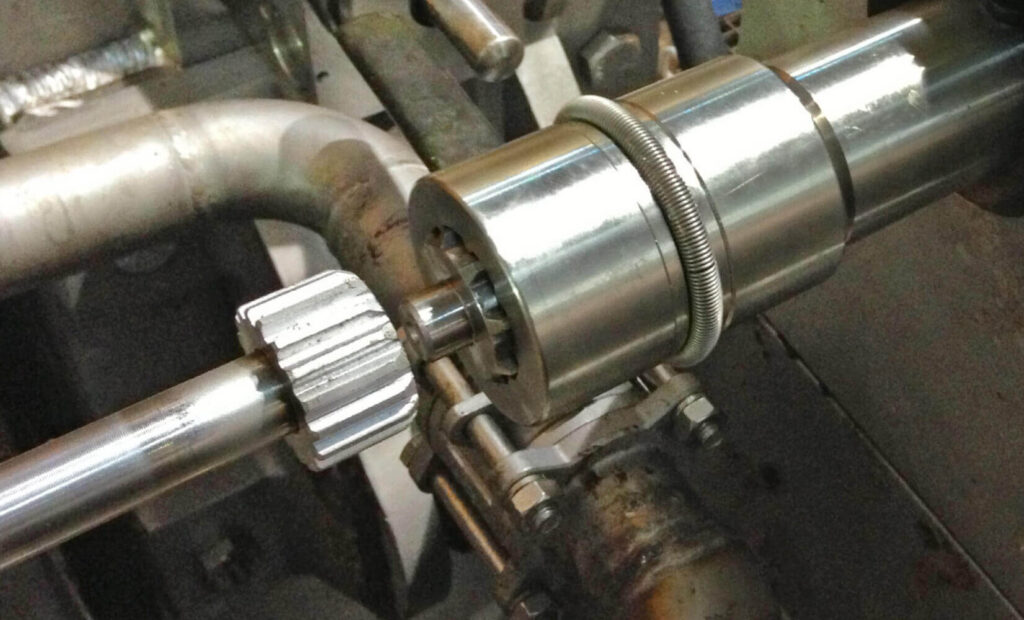

Problems with bolted clamp couplings

Bolted clamp couplings can be very susceptible to malfunctions, leading to problems that are multiplied when rods are driven on both sides:

- Delicate fastening is not suitable for industrial environment

- Screw heads are subject to clogging and dirt

- Hexagon socket screws are worn out or stripped

- Allen keys are missing

- Drive shafts are in an inconvenient position

Learn more about+ Close-

DIRECT DRIVE WITH

QUICK COUPLINGS

SIMPLE AND ROBUST

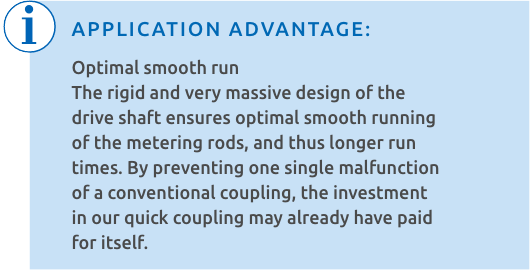

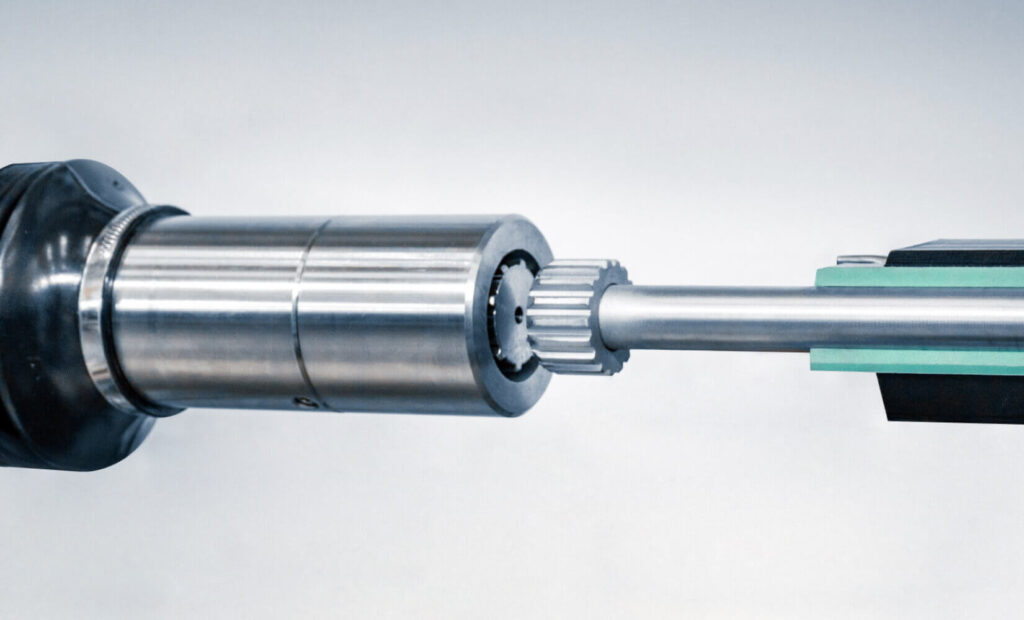

Our tried and tested direct drive is probably the most reliable rod drive at all – because it works completely without wear-prone and dirt-sensitive components. Especially the elimination of the normally.

The drive is equipped with a positioning device that aligns the drive coaxially to the metering rod in the operating position. If two different rod diameters are used, the positioning device is equipped with a front and rear stop. This way the two operating positions can be set as quickly and reproducibly as possible.

The quick coupling consists only of a simple driver, which is locked with a spring washer. The driver has internal teeth with rotational play so that it can be pushed onto the end of the metering rod without rotating the drive.

The quick coupling consists only of a simple driver, which is locked with a spring washer. The driver has internal teeth with rotational play so that it can be pushed onto the end of the metering rod without rotating the drive.

Advantages at a glance

- Tool-free “one-hand exchange”

- Rigid drive shaft without universal joint to ensure reliable operation

- Robust spring ring for quick and easy change

- Massive shaft diameter for smooth running and longer run times

Learn more about+ Close-

FLEXIBLE DRIVE WITH

QUICK COUPLING

PRACTICE ORIENTED ALTERNATIVE

In some applications it is reasonable to use a flexible rod drive. For example, if it is necessary for technological reasons to frequently use different metering rod diameters. Or, if the basic design of the coating station is not suitable for a direct drive.

This is where our completely reworked drive shafts with hexagonal quick Couplings come into play. They are available in two sizes, SW36 and SW22, and are fully compatible with numerous solutions used in practice. They can be replaced at any time without any problems.

In addition, our hexagonal quick coupling is extremely easy and tool-free to operate, robust and reliable. The built-in rotational play allows coupling by hand without having to laboriously turn the motor. A simple clamping ring is sufficient to lock the coupling. The unlocked coupling opens like a crocodile’s mouth, exposing the metering rod end without any further axial movement. Advantage when dealing with dirt during operation: Sliding movements are not hindered by dried coating.

The hexagonal holder is about 10 mm longer than the hexagonal metering rod end. This is sufficient for easy insertion of the metering rod and also compensates for thermally caused length changes.

- Tool-free “one-hand exchange”

- Flexible, for different rod diameters

- Simple spring ring for quick and easy change

- Simple drive shaft without sliding guide

Learn more about+ Close-

AUTOMATIC COUPLING

COUPLING, AS IF BY MAGIC

The latest in the field of rod drives is our automatic rod coupling. As a further development of the direct drive, the driver is no longer manually operated when using the automatic coupling. It is locked by spring force and unlocked by compressed air.

This means that the operator does not have to open or close the rod coupling manually during rod change. He can immediately remove and reinsert the rod system without having to worry about the coupling of the metering rod.

Only the driver is exposed and therefore visible. All other components have been integrated into the system in an absolutely dirt-resistant manner.

- Automatic coupling process

- Rigid drive shaft without universal joint to ensure reliable operation

- Massive shaft diameter for smooth running and longer run times

Learn more about+ Close-