EDGE DOCTOR

CONTROLLED COATING OF FILM

Due to production factors, the coated film must be wider than the sheet. This results in an “excessively” applied coat in the edge area of the rolls that must be removed in order not to impair production.

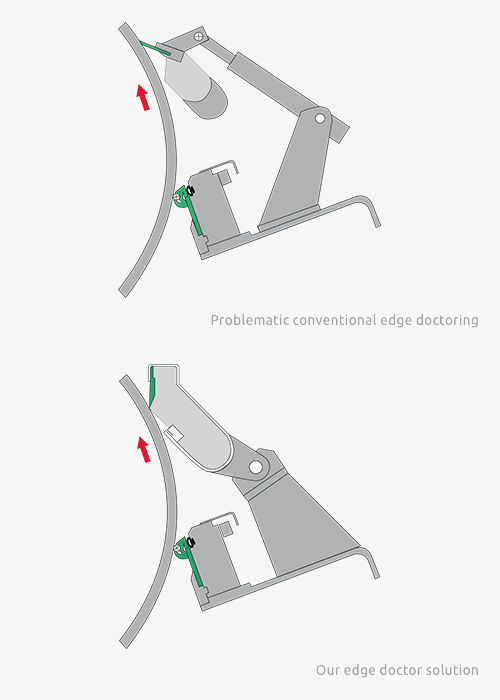

Usually, the coat from the edge area is removed by trailing blades. This technology is widely used but outdated; this can easily be explained with the laws of physics and mechanics:

- High forces must be exerted to reliably remove the excess media.

- High forces cause extensive wear to the blade; the function can decrease uncontrollably.

- The arrangement of the blade leads to a converging gap which acts like a “trap” for agglomerates and fibers. These can grind into the roll and thus increase roll wear.

The advantages of edge doctors

Our edge doctors have already proven themselves in numerous applications in the paper industry. The edge doctor is configured for optimal performance, without penetrating the roll. The required contact pressure is provided by the net weight of the blade alone. This design principle uses the leverage of a doctor much more efficiently and offers numerous advantages:

- Uniform contact pressure

- Compensated blade wear

- „Soft“ PE blade protects the roll

- Change can be performed on running machine

- Functional catch box

- Improved functionality

- Tried and tested throughout the world

- Additional sealing blade for increased cleanliness

Learn more about+ Close-